-

Guillermo우수한! 빠른 납품! 나는 당신과 다시 일하고 싶습니다!

Guillermo우수한! 빠른 납품! 나는 당신과 다시 일하고 싶습니다! -

Perus Colette그것에 의하여 LiFong를 가진 사업하는 나의 쾌락, 그들 항상 최선을 다합니다 저희를 위한 입니다.

Perus Colette그것에 의하여 LiFong를 가진 사업하는 나의 쾌락, 그들 항상 최선을 다합니다 저희를 위한 입니다. -

Robin Seifert나는 LiFong에 의해 제공된 제품 및 서비스를 좋아합니다. 그들은 고려사항으로 진짜로 우리의 관심사를 선택합니다.

Robin Seifert나는 LiFong에 의해 제공된 제품 및 서비스를 좋아합니다. 그들은 고려사항으로 진짜로 우리의 관심사를 선택합니다. -

Sjak그것은 진실합니다 우리 당신과 가진 사업하는 즐깁니다.

Sjak그것은 진실합니다 우리 당신과 가진 사업하는 즐깁니다. -

켈리 습지LiFong는 중국에 있는 우리의 원한 납품업자 중 하나입니다

켈리 습지LiFong는 중국에 있는 우리의 원한 납품업자 중 하나입니다 -

라이문트 쉥크제품 품질, 경쟁력 있는 가격, 항상 우리의 주요 공급업체 중 하나

라이문트 쉥크제품 품질, 경쟁력 있는 가격, 항상 우리의 주요 공급업체 중 하나

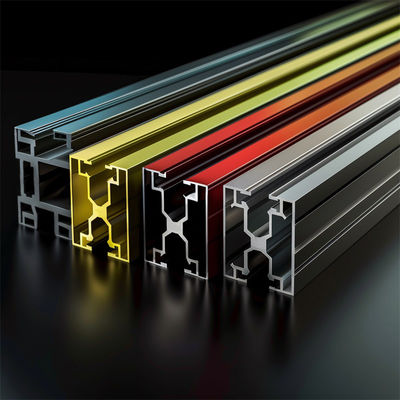

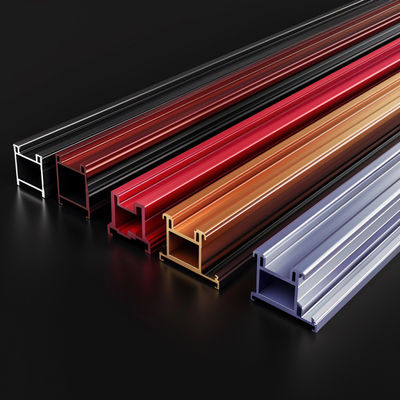

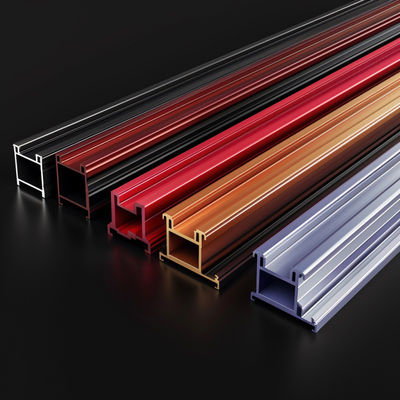

Customized Thickness Aluminium Extrusion for ODM and OEM Requirements

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 선박 | 금속 스탬핑 | 분말 코팅 | 사용자 정의 |

|---|---|---|---|

| 부식 저항 | 훌륭한 | 선택 과목 | OEM 또는 ODM |

| 원래의 | Dongguan, 중국 | 부분 무게 | 사용자 정의 |

| 양극화 | 은 | 유형 | 압출 알루미늄 프로파일 |

| 강조하다 | customized thickness aluminium extrusion,ODM OEM aluminium extrusion,aluminium extrusion with warranty |

||

Water-Cooled Cold Forged Heat Sink Aluminum Water Cooling Block Liquid Heatsinks Cold Water Plate Heat Sink

![]()

![]()

Key Specifications/ Special Features:

We can provide you with professional advice and design drawings based on your ideas or drawings. We are not only a custom production but also a professional mentor.

Our machined products embody superior precision and craftsmanship. They are designed with attention to detail, guaranteeing excellent performance and accuracy. From start to finish, every step is executed with the utmost care, resulting in superior quality and unparalleled reliability. Our machined products are custom-tailored to meet your unique requirements, delivering unrivaled excellence in engineering and functionality.

•Profession: We're the custom CNC machining manufacturer and aluminium extrusion heat sink for over 20 years.

•Production: Based on customers' drawings, and also can make special design for customers.

•Materials: Aluminum, Stainless steel, Tool steel, Brass and other material can be used.

•Dimensions: It can be customized.

•Process: Sheet Metal Fabrication: Laser Cutting, Bending, Welding, Etching, Metal Punching

•Certification: ISO 9001:2015 certified

•Testing Equipment: Test Instrument CMM, 2D Projector, Altimeter, Spectrograph, etc.

•Service: warm and quick response service provided by the professional export sales team with many years' experiences in handling exports to the US, Europe, Japan and other countries and regions.

•Surface Treatment: Deburr, Powder Coating, Anodize, Heat treatment, Wet Paint, Zinc Plate, E-coating, QPQ, Passivate, Brushed, Electropolishing, Black Oxidation etc.

•Price Term: EXW, FOB Shenzhen/Guangzhou, CIF.

•Delivery: 4-6 days.

•Application: Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

3,IATF16949,AS9100,SGS,CE,CQC,RoHS

Processing Technic:

- Copper Fins: Progressive Die Stamping

- Aluminum Board: Extrusion+ CNC Machining

- Copper Tube Forming : Automatic Tube Bending+ Burn into Tip Ends.

- Aluminum Board and Enclosure Nickle Plated, Copper Fin Passivate (Insulation,Oxidation and Corrosion Resistance).

- Assembly: Automatic Fin Wearing/Assembly, then Fixed by Overflow Soldering and Screw/Rivet Combination.

- Quality Check

- Packing

Advantages:

- Professional Research and Design Team, Strong & Automatic Equipments: Progressive Stamping, Automatic Tube Bending Machine, Automatic Fin Wearing Machining

- Strict Quality Control in Each Process and Finish Product Quality Control

- Short Delivery Lead Time: 15-30 Days

- Optional For OEM or ODM

- Comprehensive After-Sale Service, Quick Responses For Daily Communication

About Us:

![]()

![]()

CNC machining parts, cold heading parts, stamping parts, fasteners, die casting parts.

R&D strength: There are 15 people in the R&D team, including R&D engineers, project management engineers, process engineers, and test engineers. Among them, the project manager has completed the development of several new projects of Honeywell, BSH, Whirlpool hardware. Has an independent new product development testing laboratory.

1)

Material: Aluminum/brass/copper/zinc/Bronze/Stainless Steel/steel

Process: high speed precision stamping, progressive die,stamping,CNC, deep drawing,die casting,

Finish: polishing/Plating/Sand blasted/powder coated/anodized/hot dip gavanized

Size: Customized

Sample Time: 15-30days

Delivery Lead Time:10 days after sample approval and received the bank transfer

Packing: pvc bag+carton

Payment term: 30% deposit,the balance should be paid before shipment

2)

Our products are widely used in various industry,

such as Lighting

3G outdoor antenna

Electronic hardware

home appliance

Central air conditioner

Transport machinery

Other material handling machinery

3)

Why choose us ?

Best Service and Best Quanlity with Best Price

Leading engeering and stable staff to work with

100% QC Inspection Before Shipment

![]()

CNC Machined Parts Surface Treatment

painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

implantation, ion plating, laser surface treatment, etc.

![]()

![]()

![]()

Application Field

![]()

Aerospace: The aerospace industry requires precision parts with high accuracy and tight tolerances. CNC machining services are used to produce parts such as turbine blades, engine components, and structural parts.

FAQ

Q: Are you a factory or trading company?

A: We have factory in Dongguan of China, Welcome to visit us.

Q: What are your main products?

A: We specialize in manufacturing metal stamping parts, metal stamping, laser cutting, sheet fabricating, CNC machining, bending, welding, tool & die making and assembly products.

Q: Can you support OEM/ODM according to my design drawings?

A: Yes. We have a professional technology team to support OEM/ODM order, which can make customized products according to customer drawings.

Q: How can I get the quotation?

A: We will submit the quotation within 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us with the following information together with your inquiry:

(1)3D Step of Files and 2D Drawings (2)Material requirement (3) Surface treatment (4)Quantity(per order/per month/annual)

(5)Any special demands or requirements, such as packing, labels, delivery, etc.

Q: Can I get the samples?

A: Yes, the sample order is available for quality check and market test and it will be freight collected for payment.

Q: How do you control the product quality?

A: (1) Materials inspection by IQC.

(2)During processing, our IPQC will check the injection molded parts all the time

(3)FQC will check the products before sending them to the warehouse

(4)100% inspected by OQC before shipping out.

Q: How to do if we receive defective products?